I love the simplicity of firearms. While they might seem like complicated machines, they are actually pretty straightforward when you break them down.

You know what else is simple? Cartridges.

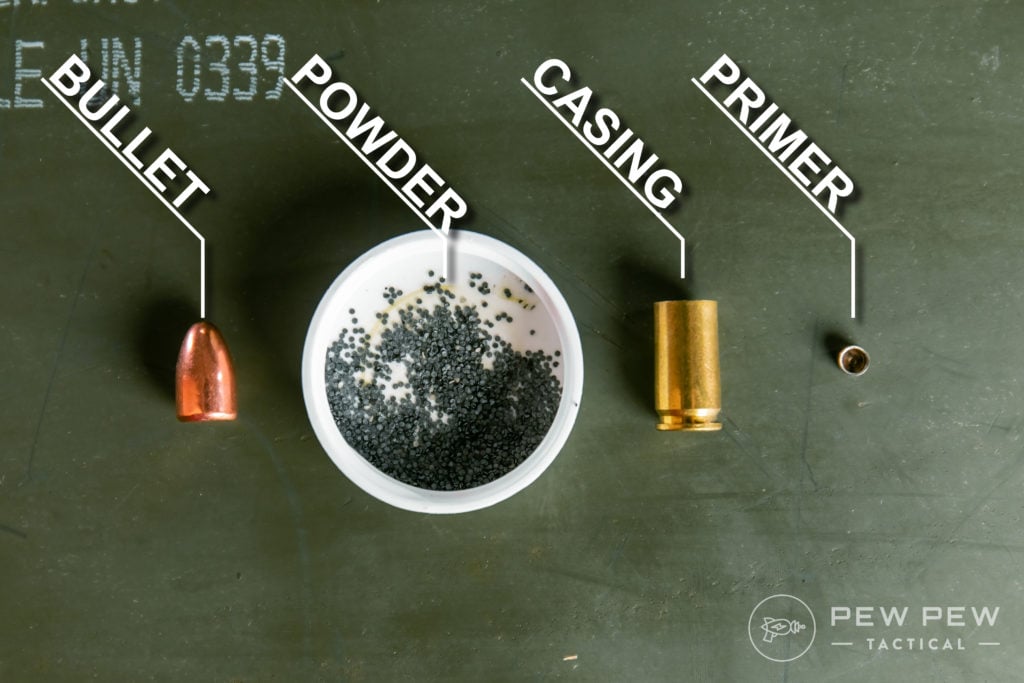

Most pistol and rifle cartridges consist of four components. You have a case, a projectile, gunpowder, and a primer.

The case is the body of the entire cartridge that holds everything together. It is the main building block for most modern ammunition.

Cartridge cases come in many flavors, which brings us to the topic of today’s article. I am going to go over the different types of cases and materials they are made out of.

Table of Contents

Loading…

Types of Cartridge Cases

Almost all cases fall into one of the three following categories:

Bottleneck Cartridges

Bottleneck or tapered cartridges happen when the bullet is notably smaller than the case diameter. The end of the case steps down (bottlenecks) to accommodate smaller projectiles. Bottlenecked cases allow for a larger case and more powder capacity relative to the bore diameter.

Straight-Walled Cartridge

A straight-walled cartridge is exactly what it sounds like. The walls, or sides, of the cartridge are perfectly straight. The case body is the same diameter as the bullet. Straight-walled cartridges typically have bigger bullets and lower velocities than bottleneck cartridges.

Tapered Cartridges

Some cartridges have something called case taper. Case taper is when the sides of the cartridge aren’t perfectly straight but very slightly slope toward the mouth of the case. This small amount of taper aids with feeding and extraction in handguns, and is commonly seen in cartridges such as 9mm, .40 S&W, and 10mm.

Types of Rims

At the bottom of every cartridge case, there is either a groove or a rim. There are different types of grooves and rims, and each affects how the cartridge ejects, extracts, and chambers.

Let’s take a look at some of the different types of cartridge rims.

Rimmed

Rimmed cartridges have a pronounced rim (a ring) at the bottom of the case that is larger in diameter than the case body. These types of rounds are commonly (but not always) used in revolvers and lever-action rifles and aren’t particularly well-suited to semi-auto or magazine-fed guns.

Rimless

Rimless cases feature an extractor groove at the bottom of the case. Despite the name, there is technically still a rim for an extractor to grab, but it is the exact same diameter as the case body rather than being visibly wider.

This is the most common type of cartridge, with examples including 9mm, 5.56 NATO, .308 Win, .45 ACP, .380 ACP, and many others.

Semi-Rimmed

These cartridges have a pronounced extractor groove, like rimless cartridges, but also have a rim that is slightly larger in diameter than the case body. Semi-rimmed cartridges were invented to make rounds feed more reliably in box magazines. They have almost been completely replaced by rimless cartridges.

The most common semi-rimmed cartridges you will see today are .25 ACP, .32 ACP, and .38 Super.

Rebated Rim

A rebated rim case has an extractor groove and a rim that’s smaller than the diameter of the case. These are usually larger cartridges that were adapted to fire in guns that fired smaller rounds with smaller bolts and breech faces. Using a rebated rim usually allows you to swap calibers without changing bolts or the overall gun design.

Examples of rebated rim rounds include .350 Legend, .458 SOCOM, .50 Beowulf, .50 AE, and 5.7x28mm.

Belted Magnum

Much like the name implies, belted magnums feature a distinct raised ring (belt) that sits just above the extractor groove. This belt helps keep pressures safe by preventing over-insertion into the chamber and ensuring the cartridge’s headspaces correctly.

Belted magnums are most prominent on extremely powerful magnum rounds such as 7mm Rem Mag, .300 Win Mag, .375 Holland & Holland, and more.

Case Materials

Different metals and materials have different properties, and it is no different when it comes to ammo. Manufacturers use various case materials to achieve specific results, whether that’s cheaper ammo, lighter ammo, or better ammo.

Brass

Brass-cased ammo is by far the most common cartridge type in the United States. It’s not only popular but arguably the best all-around option, period. Brass offers a ton of advantages compared to other types of cartridge cases.

While elastic doesn’t sound like it would apply to metals, some are indeed more elastic than others. Brass offers greater elasticity, allowing the cartridge case to be easily resized and reused numerous times before it starts cracking.

Brass ammo also increases ballistic performance. When fired, the brass case expands, creating a solid gas seal that improves performance. After firing, the case contracts and is ductile enough for easy and reliable extraction.

Brass-cased cartridges also have a natural lubricity that helps ensure smooth feeding without the need for a coating. Compared to other materials, brass is also fairly corrosion-resistant.

Steel

Steel-cased ammo wins the 2nd place award for popularity. This is due to the primary benefit of steel-cased ammo is its price — it’s cheap! Much cheaper than brass, in fact.

The cost savings during mass production have made it popular for militaries in countries that have historically used Soviet small arms. However, Americans love shooting a lot, and plenty of steel-cased ammo is produced domestically to help satiate the frugal shooter.

However, price is the only benefit. Steel-cased ammo can be reloaded, but it’s very difficult. It’s difficult enough that the consensus is that it’s not viable to do so.

After repeated use, steel can crack and break. It also rusts faster than brass and lacks the lubricity of brass.

Steel is also harder and holds its shape more than brass. This makes it harder to extract while also putting more wear and tear on small parts that contact the case, such as ejectors and extractors.

That said, I still shoot a lot of steel case for the cost savings and have not had any major problems when using quality brands.

Aluminum

Some of our favorite guns make extensive use of aluminum in their construction, so why not use it for ammo cases?

The main draw to aluminum ammo is that it is cheaper than brass.

Like steel, it also cannot be readily reloaded since it is a softer metal and is much more prone to cracking when expanding and contracting. However, aluminum is much more corrosion-resistant than steel.

Aluminum is also lighter than brass. And while the weight of a single round doesn’t matter much, if you are carrying around hundreds of rounds, those tiny grams can add up to some serious weight savings.

Hybrid Cases

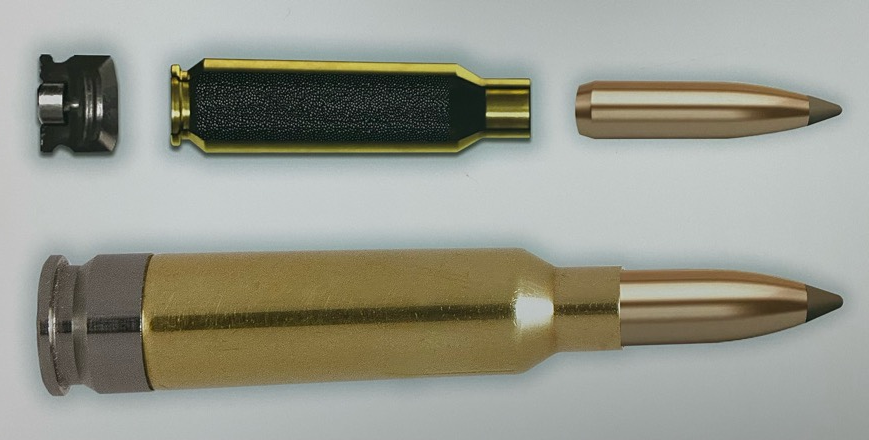

Hybrid cases make use of two different case materials in a single cartridge. This is usually done to try to make use of the best properties of both materials.

There has been much talk about the revolutionary hybrid cases. The US Army has been evaluating various hybrid 6.8 mm rounds for its Next Generation Squad Weapon (NGSW) program.

Sig Sauer designed a hybrid case with a brass body and a locking washer that secures a steel base (case head). Since steel is stronger than brass, this allows the round to run at extremely high pressures without blowing the bottom of the case out.

True Velocity also produces rifle rounds that use polymer bodies with a bit of metal. While the body is polymer, it uses a stainless steel head insert. Polymer-cased ammo is much lighter, dissipates heat faster, and causes less metal-on-metal wear.

However, hybrid cases aren’t exactly new. Shotguns have been mixing polymer hulls with brass bottoms for a very long time.

So what are the downsides? Well, it depends on the ammo.

Polymer shotgun ammo tends to flex and deform when put into box magazines. The Sig hybrid ammo is super expensive and has had extraction issues, carbon buildup in the chamber, and increased stress on small parts.

There have also been reports of the True Velocity polymer-cased ammo having cases split, case heads ripped off during extraction, and the polymer expanding too much, which causes general extraction difficulties.

Paper and Cardboard

Paper and cardboard cartridges have long been out of mainstream production for decades.

In ye olden times, paper ammo was cheap and easy to produce. But to no one’s surprise, paper and cardboard ammo were susceptible to both moisture damage and physical deformation.

Paper rifle cartridges are purely antiques or recreations for recreational weapons. There isn’t a serious use for them in the modern era.

Case Coatings

The base material of cartridges is one factor, but brass cases can have different coatings that can help improve performance. Let’s take a look at some of the most common coatings.

Nickel

Nickel coating is quite common on high-end self-defense ammo because it serves two important functions for shooters.

First, it helps enhance the corrosion resistance of your cartridge case. Defensive carry ammo is more likely to be exposed to sweat and other outdoor elements, both of which can cause corrosion. Brass-cased ammo is already corrosion-resistant, but it’s not rustproof. Nickel-plated ammo adds another layer of material to further protect the brass underneath.

Nickel also has a higher natural lubricity than brass. A higher lubricity helps ensure more reliable feeding, extraction, and ejection.

Polymer

Polymer coatings are most commonly used on steel-cased ammo to help alleviate some of the problems typically encountered with steel.

The problems are mainly extraction issues and susceptibility to corrosion. Coating the steel cases in a special polymer helps provide more natural lubricity while also providing an additional barrier against moisture.

Wolf is a major manufacturer of steel-cased ammo, much of which is polymer-coated. FN also uses a specialized polymer coating on 5.7x28mm ammo to help them run better in the odd magazines and feed system of the FN P90.

Polymer coatings can reportedly cause “buildup” in your chamber. I’ve not experienced this issue, but I do occasionally clean my guns, which is likely the trick to preventing polymer buildup in your chamber.

Techni-Crom

Techni-Crom is a premium case coating that is sometimes used on defensive ammunition. Like nickel, it provides additional corrosion resistance and lubricity.

Where it departs from nickel is that it uses a secondary coating in addition to the nickel compound. Nickel can still have some porosity, and moisture can still get in. The addition of a second proprietary coating further reduces porosity while increasing lubricity.

Sig uses this coating on some of their defensive ammo. It’s expensive but effective.

Lacquer

Lacquer coatings achieve the same corrosion resistance and lubricity improvement that polymer coatings do for steel-cased ammo. Most lacquered ammo tends to be from Eastern Europe.

So what is in the lacquer? Great question, and the answer is, it depends. Historically, Eastern Europe has used a wide range of lacquer materials, including polyvinyl butyral, epoxy, melamine, phenolic coatings, and more.

Like polymer coating, it can build up in your chamber. Again, I’ve never seen that, and it’s unlikely to be a problem if you clean your gun occasionally.

Meet the Experts

This article was authored by Pew Pew Tactical Freelance Writer & Review Analyst, Travis Pike. Travis is a United States Marine Corps veteran and lifelong shooter. He is an NRA Basic Pistol Instructor and Concealed Carry Instructor out of Florida.

Travis has spent years writing for numerous publications and testing tons of gear, guns, and a wide variety of ammo through many different weapon platforms. Between his military and industry experience, there is no telling exactly how many rounds he has put down range through how many guns, but it is a lot.

Final Thoughts

Cartridge cases may just seem like asimple piece of metal that holds everything in place, but sometimes there is more beneath the surface to consider when choosing the right ammo.

What type of ammo do you use? Are there any that you avoid? Let us know your experiences in the comments below! Looking to learn more? Be sure to also check out our guide on the Bullets: Sizes, Calibers, and Types!

Leave a Reply