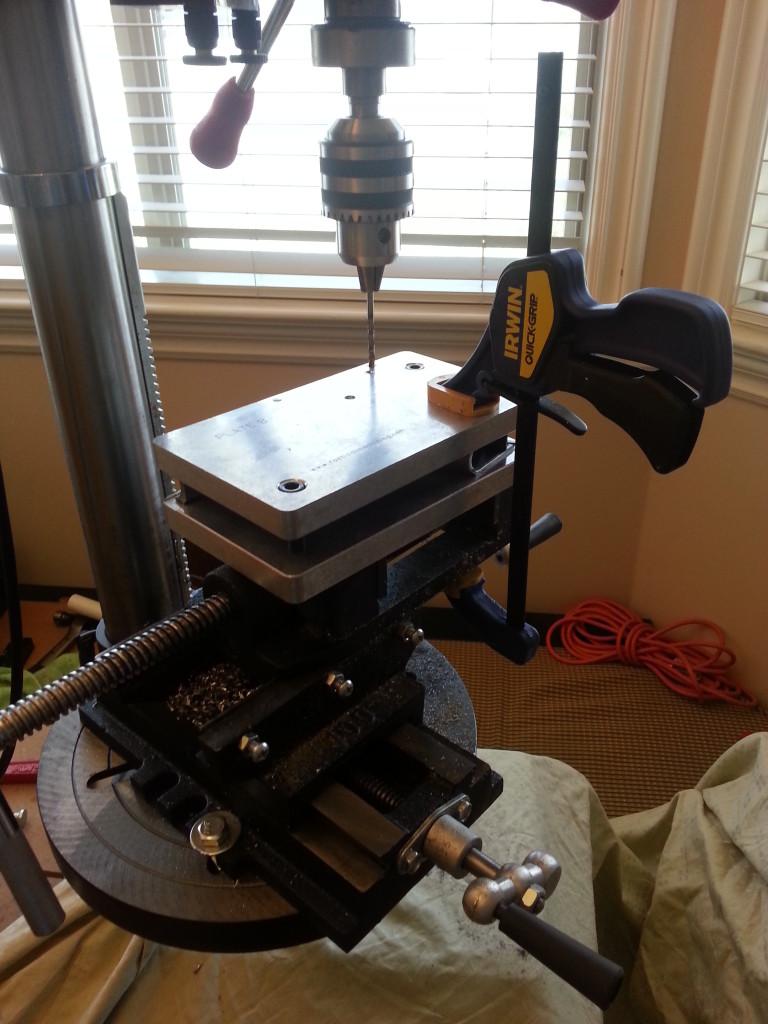

Setup

Keep the jig on like you did for the slide cutting and barrel seating. You’ll just remove it from the vise and lay it flat. Remember to bubble level it and clamp it down! Disclaimer again.Drilling

Choose whichever bit size first. Here I went with the 4mm hammer pin hole. I’m going to drill just through one side.

Next Lesson

Part 1: Intro (Finding the 80%)

Part 5: Cutting the Slide Rail

Part 7: Hammer & Sear Pin Holes

6 Leave a Reply

Great site you have got here.. It's hard to find high quality writing like

yours these days. I seriously appreciate individuals like you!

Take care!!

:D Thanks for the kind words!

Hello, I enjoy reading all of your article. I wanted to write a little comment to support you.

Thanks so much!!!

Thanks for documenting all of this! It has been a great help as I do mine. I have a question about the sear and hammer holes and pins. I drilled the holes and they work great as far as the pins going through. The pins have a lip on them, should that lip be flush with the frame, or does the lip sit on the frame? Thanks!

Thanks for your question! The lips should sit flush on the side where you have the thumb safety. That way the pins won't fall out. I actually had the pins going in the wrong way until my smith told me if should go in the other way. I ended up using the rounded bit from the burr set used in the installation of the plunger tube to make the pins sit flush.