Want to build your own AR lower receiver…without letting big brother know?

You’re in luck! We hands-on review 80% Arms’ Easy Jig Gen 3, using it to create a fully-functioning AR-15.

By the end of this, you’ll know if an 80% project is right for you, if the Easy Jig can help you out, and some tips/tricks we learned along the way.

Need a little more than just words in an article? We got you covered with a full video and review below courtesy of our very own Johnny B.

Disclaimer: We’re not lawyers and you should check with your local, state, and federal laws regarding 80% receivers. Rule of thumb: if you can normally buy and own an AR-15, you can probably build one for personal use.

Note: The ATF raided Polymer80, an 80% manufacturer, in December 2020. There has been one reported case of the bureau also visiting a customer and forcing them to surrender their “P80.” Pew Pew Tactical is following the situation and will provide updates if there are any legal changes in the future.

Table of Contents

Loading…

Quick Overview of 80%

Hopefully, you already know what an 80% receiver is…but here’s a super fast refresher.

The industry term “80% receiver” refers to a hunk of metal that isn’t quite ready to pair with other firearms parts. It has the basic look of a receiver but without spaces for key components like the fire control group.

Because of this, you can buy these paperweights anywhere since, at this point, they aren’t functional firearms.

80% receivers can even be shipped to your house because they, again, aren’t technically a gun by government standards.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

BUT, there’s a catch — you will need to finish them yourself.

And that’s where 80% jigs come in.

Jigs help you cut out the firing control group area and some trigger pin holes so you can use the receiver and parts kit to create your very own AR-15.

All from the comfort of your home.

Old School Jigs

We cover a bunch of stuff in our Best 80% Receivers & Jigs, but many years ago you had some drill-press jigs.

First you needed a full-on drill press.

Then you had to make tons of little holes into the fire control group pocket before attempting to mill (cut in a horizontal manner) it out.

It sucked and took hours.

Easy Jig Gen 3

Now…all you need is a power drill, wood router, some bits, and the jig!

Don’t worry, we’ll have a list of everything at the end.

And you avoid all the dozens of little drill holes by using the router to slowly mill the pocket immediately.

So, how does it all work?

In order to transform the block of metal we call the billet into a future AR-15, we need a jig to complete the lower…enter the Gen 3.

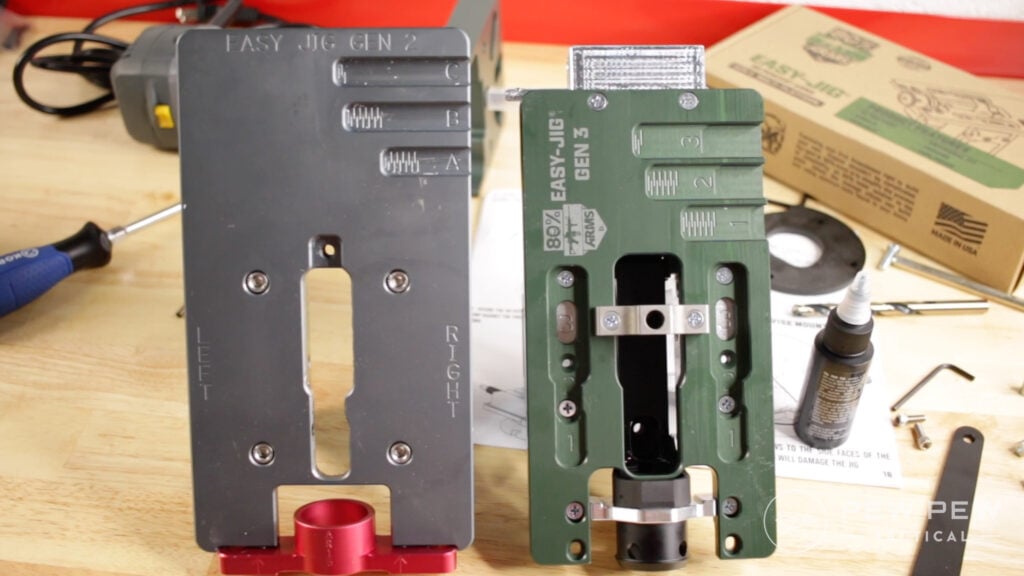

Gen. 3 vs. Gen. 2

Now, we took the previous model from 80% Arms, the Gen 2, for a run last year. While it wasn’t terrible, we wouldn’t call it fantastic. At best, it was okay.

Better than older jigs but there’s room for improvement.

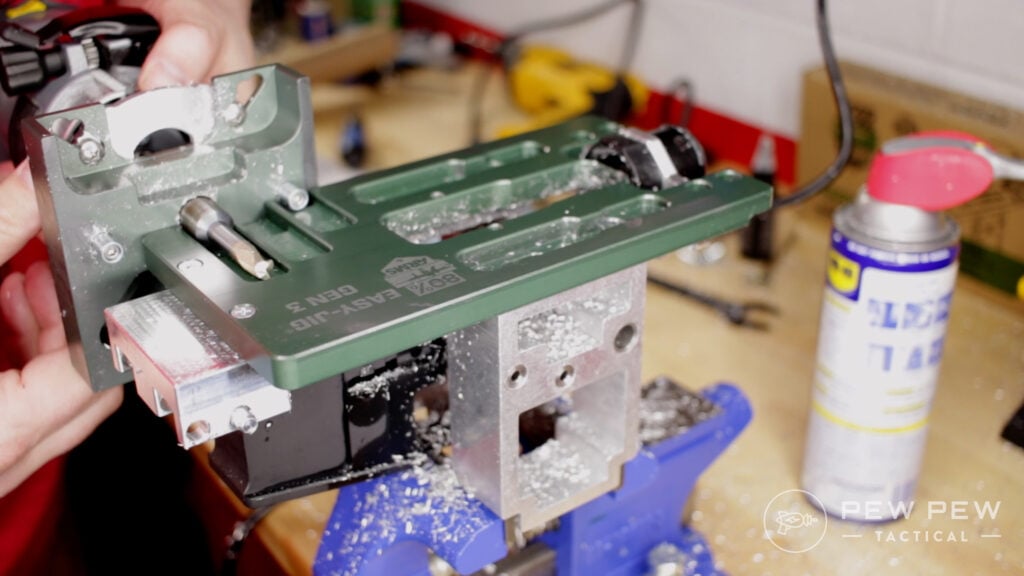

The latest jig from 80% Arms, the Gen 3, definitely enhances the original design and offers so much more in the way of useability.

To be honest, it blows the Gen 2 out of the water.

Like its predecessor, the Gen 3 ships with directions and all the drill bits you need to mill out that lower.

Still capable of milling either an AR-15 or an AR-10, depending on your preference, the Gen 3 is surprisingly smaller and nicer looking than the previous generation.

But straight up, it’s simpler. We’re all definitely happy about that!

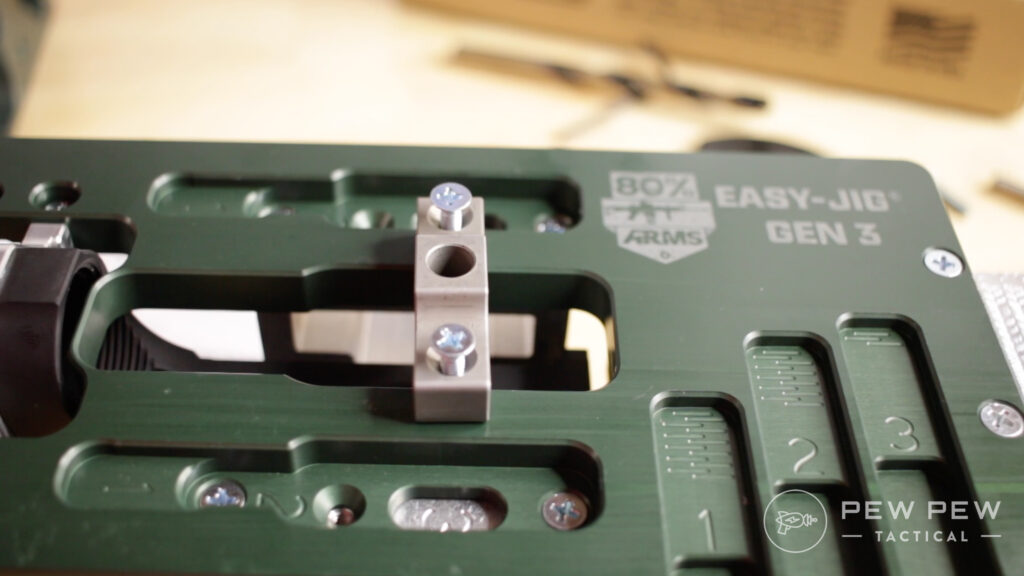

The Gen 3 also benefits from channels that actually guide the router. We can’t stress enough how important these channels are.

It makes things much, much easier. There’s no guesswork and little frustration. Not to mention, it produces much smoother results.

If you’re already rolling with the Gen 2, you can probably keep on keeping on, but if you really want the smoothest look and simplest process, then the Gen 3 is definitely worth the upgrade.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

The Process

With all the parts laid out and ready to go, it was time to get started.

Plenty of you are probably like me and a little unsure about this stuff. Don’t sweat it too much. With 80% Arms, you don’t need a machine shop at all.

The 80% comes with clear directions that you follow step-by-step.

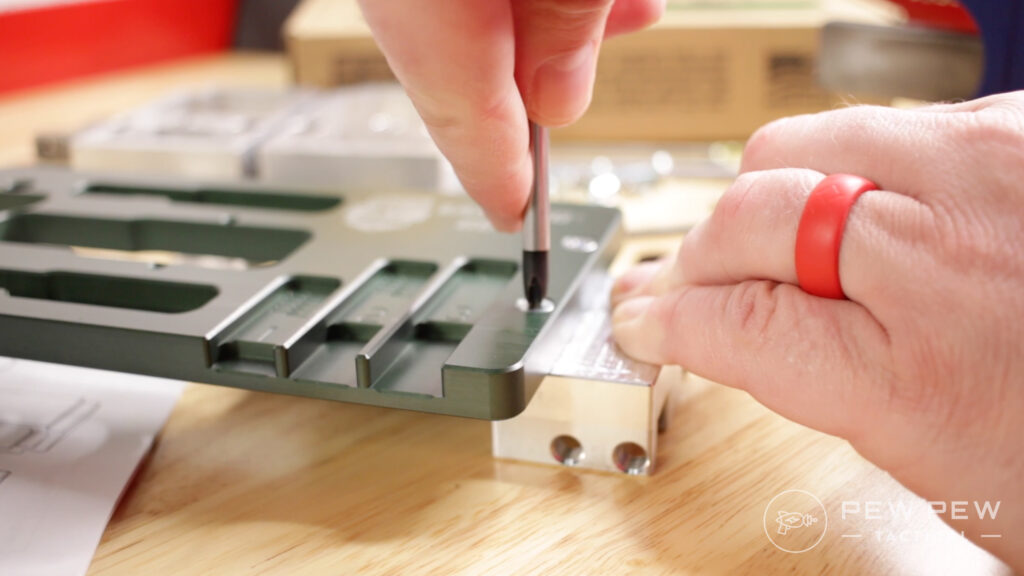

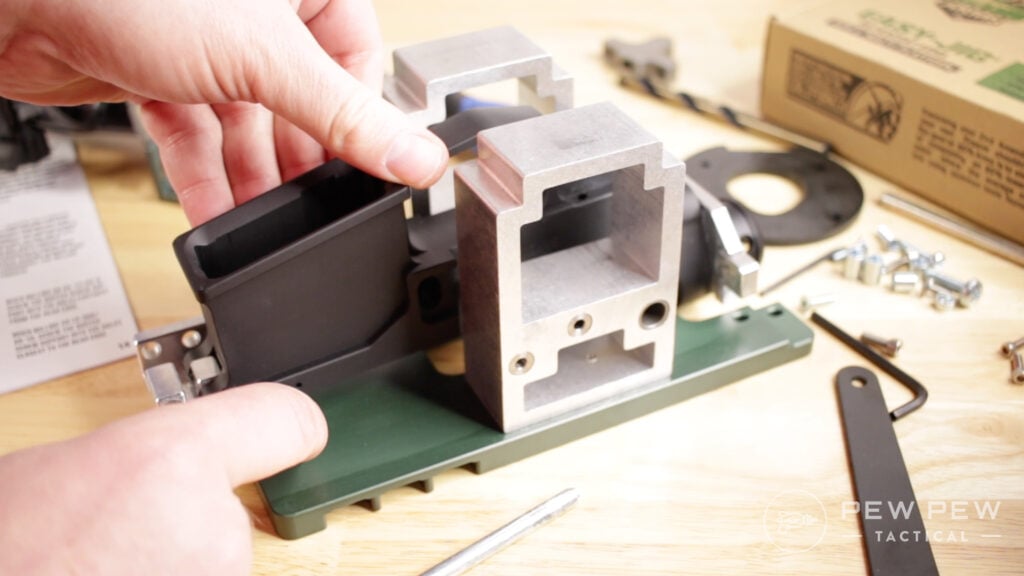

Setup the Jig

It’s easy…

There’s a big plate on top where you connect the two smaller shinier plates. One is for AR-15…

While flipping it will give you the AR-10 side plates.

Note we went with the Easy Jig Gen 3 multi-caliber version which lets you do the AR-15, AR-9, AR-45 and .308.

Connect the big plate and the sides with some pins and screws.

Then drop in your billet lower.

From there, you’re ready to rock and roll on the fun part!

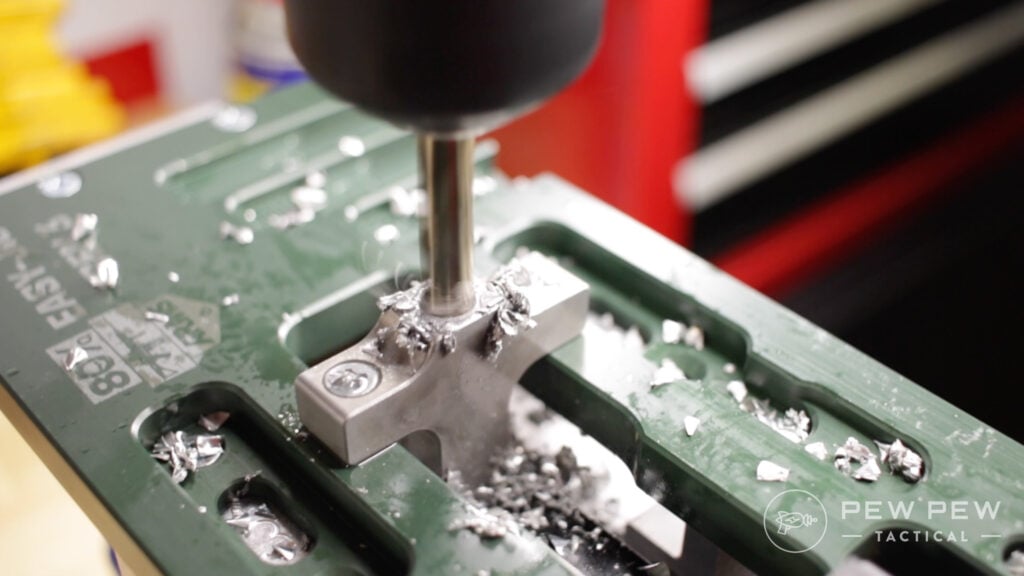

Pilot Hole

You’re going to start by drilling a pilot hole into the receiver with a regular ole drill.

Pro tip: use a little cutting fluid and go slow.

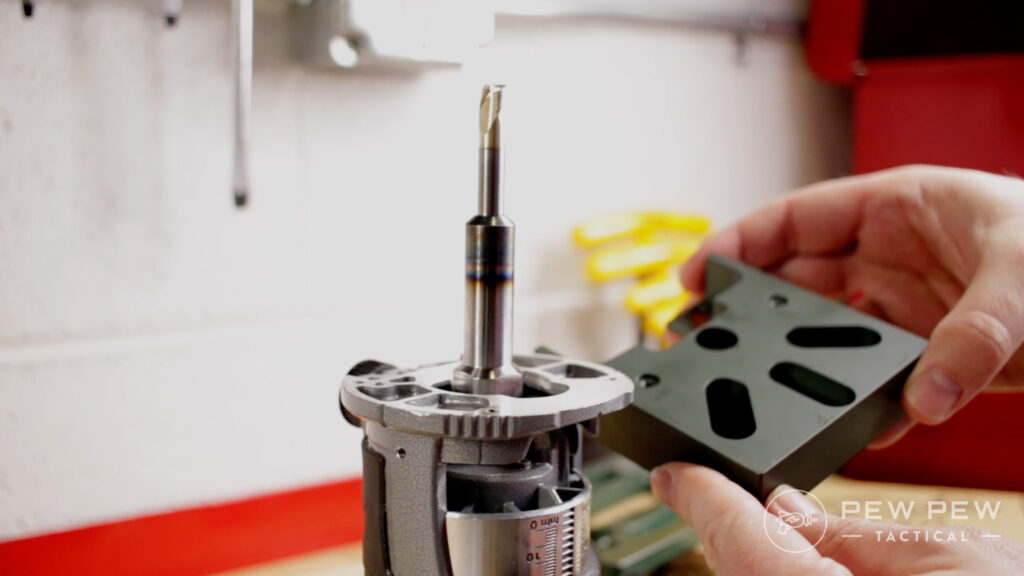

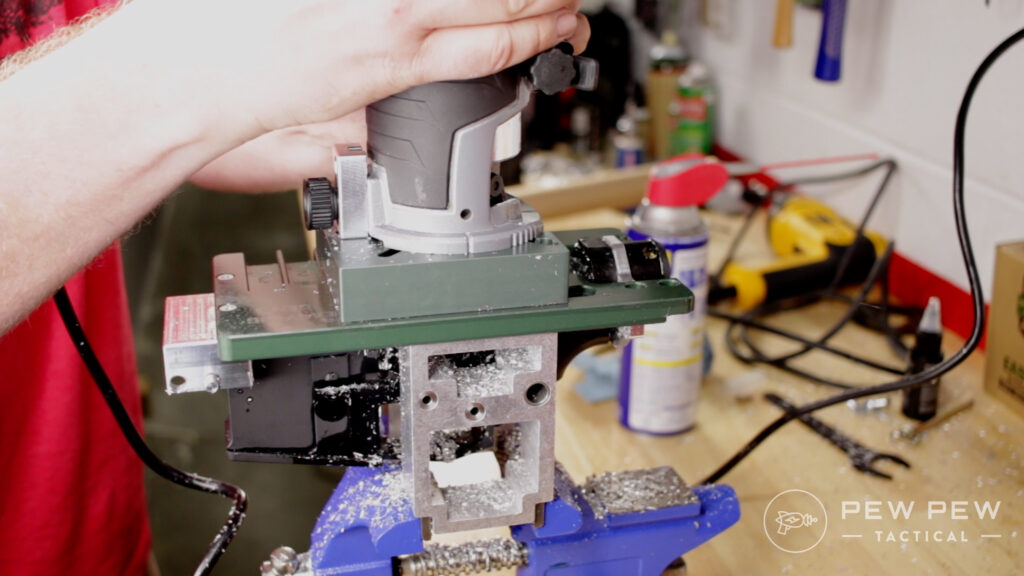

Setup the Router

Next, you’re going to focus on the router. Take off the base plate and add in the 80% Arms base plate.

The two should fit right together.

Tip: Really make sure to tighten that milling bit!

The 80% Arms base plate allows you to use the aluminum tabs that travel down in the jig channels.

They’ve really tried to make these idiot-proof, even going so far as offering clear guidelines that show you how deep to cut.

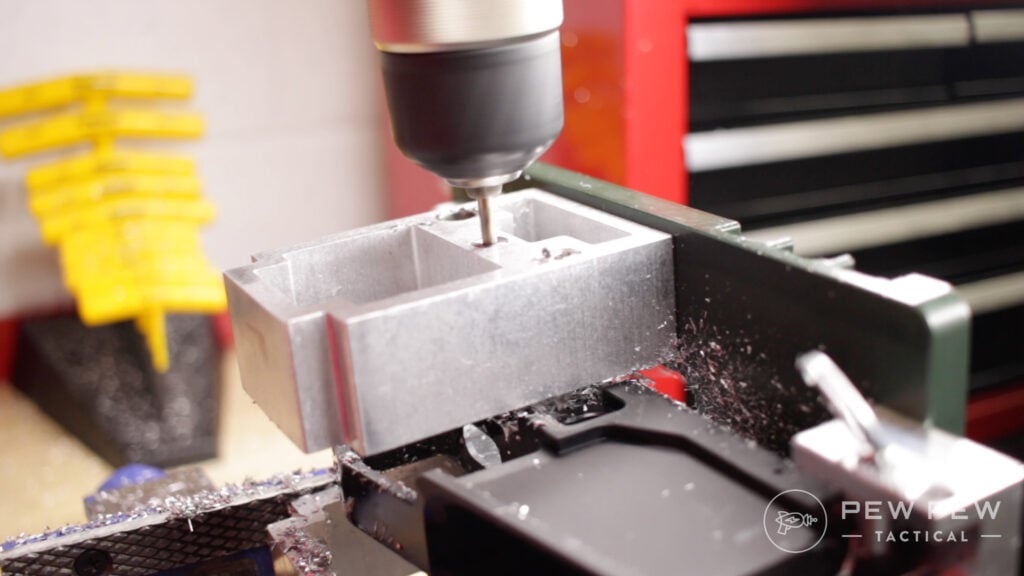

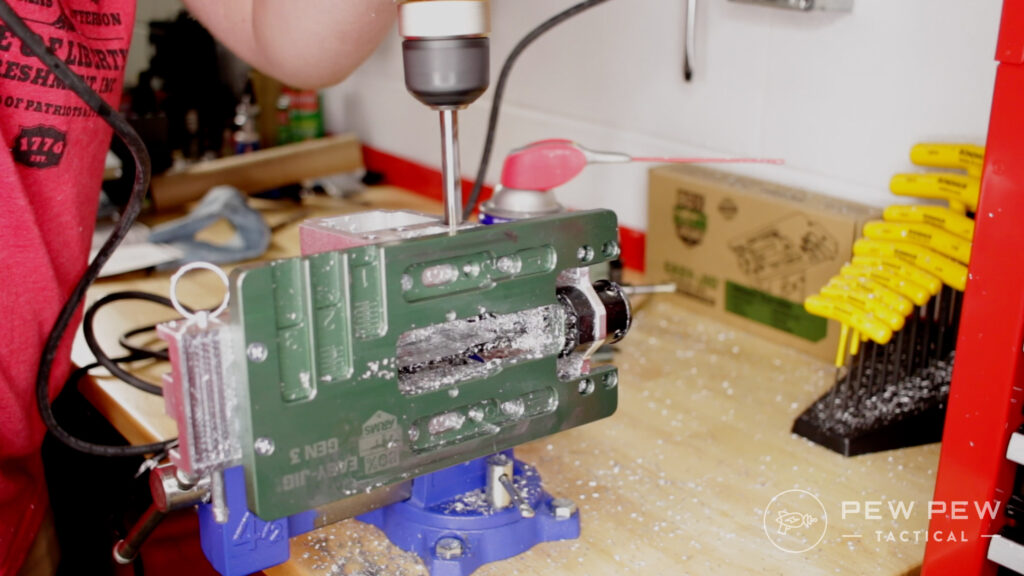

Milling

The old jigs made you measure your depth…but the top plate gives you super handy-dandy marks as measurement guides.

Buckle up, because this where the bulk of your time will be spent. You’ll put on some cutting fluid (highly recommended), lower the bit to the next hashmark, start the router and put it into the pilot hole, then mill the pocket.

Another pro tip is to have your router on the highest speed and to make sure you start milling each time from the pilot hole. Both of these techniques will prevent runaway chattering (yup…learned it the hard way).

When you get to the lowest depth, you change out the aluminum tabs to the next bigger size and keep going.

There’s going to be aluminum flakes everywhere…so make sure to have eye protection if not also hearing protection.

We highly recommend hooking up a Shopvac to take care of the mess.

Then boom…you’re done with all the three sections of milling.

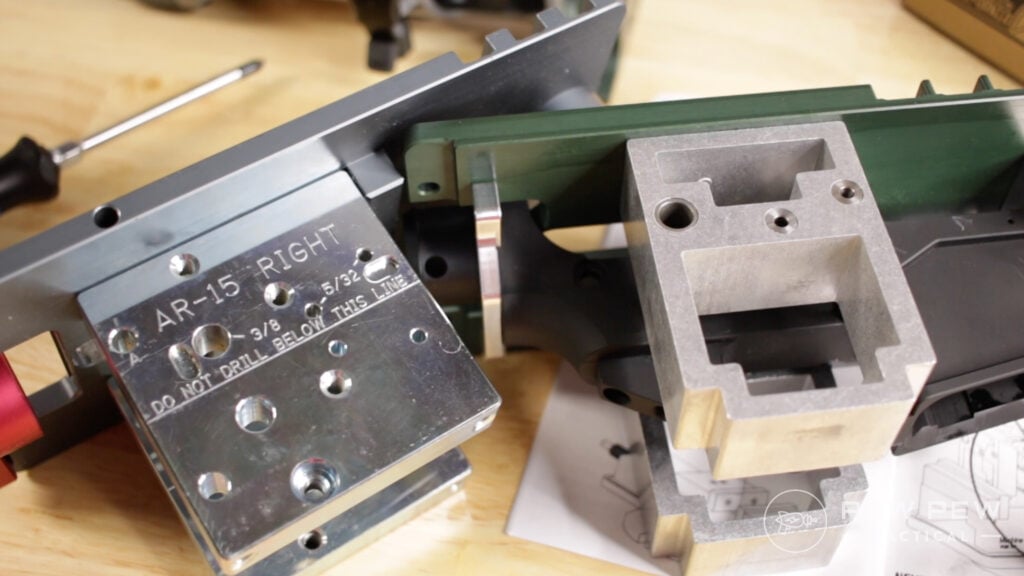

Trigger Pin and Safety Holes

Flip it to the side and get your power drill ready to make the two trigger pin holes and safety hole.

Only do one side at a time!

The nice thing about the Gen 3 is that it is very clear where these holes go.

You’re basically done at this point!

Well, except for cleaning an aluminum-flake covered lower.

Wipe that bad boy off…

And grab your lower parts kit of choice.

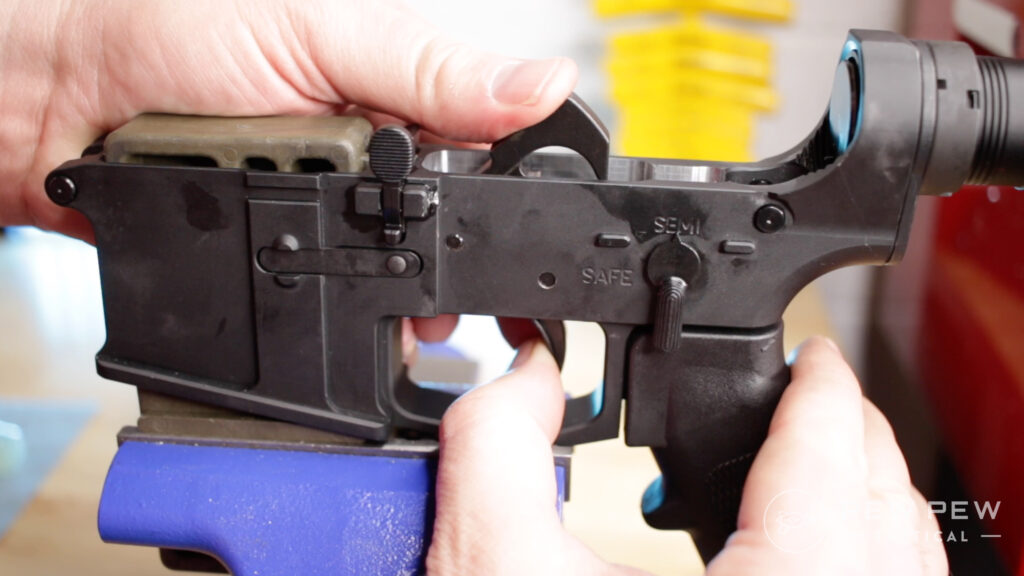

Complete It

Now that the milling is done, build your AR out like you would a regular AR project.

Building this lower felt no different than any other AR lower I’ve worked with. And everything went together smoothly.

Check out our guide to Completing an AR-15 Lower if you need some help with that.

As always, I do a ton of function checks on everything just to make sure things are lining up and working properly.

Add a nice upper (Best AR-15 Uppers) and you’ve got an un-serialized piece of American freedom.

Needed Parts & Tools

Essentials

- Easy Jig Gen 3

- Drill Bit Kit: Build your own or it’s easier to buy from 80% Arms since the mill bit is proprietary

- Wood Router

- Power Drill

- 80% Lowers: For this, we used 80% Arms’, but here are some others we like

- Cutting Fluid: You’ll probably want something…even WD-40 will do in a pinch, but here’s some real aluminum cutting fluid

Nice to Have

- Shop Vac: If you don’t want aluminum chips everywhere

- Vice: Makes it much easier than trying to clamp it down by hand or quick clamps

Time Needed

The amount of time you spend on this project will really come down to how comfortable and familiar you are with the process.

For those just starting out, it could take several hours as you want to be careful and deliberate.

Old pros who have done this a few times can probably knock it out in a couple of hours, though.

But trust me…this is the easiest way to go about it! The Easy Jig Gen 3 is already tons faster and more precise than the old school jigs.

Tips & Tricks

We went over several things already but here are our main takeaways…

- Read the instructions & watch the videos a couple times

- Really clamp down the mill bit onto the router or else it might back in

- Go 100% on the speed with the router

- Try half-hashmarks first. Stay with them if you have 7075 aluminum, and you can try full-hashmarks if you have the softer 6061.

- Start each milling pass in the pilot hole

- The router can overheat and shutoff…give it a few minutes

- Use cutting fluid

- Use eye and ear protection!

Is It Worth It?

It does add up with the jig (even if you go with the cheaper ones), bits, lowers, and tools if you don’t have them.

Building 80%-ers is usually never about cost savings.

It’s about exercising your right to make your own guns away from the eyes of Uncle Sam.

Plus…it’s super cool to know you built your own lower receiver.

All that sounds good…but it’s still a good chunk of change.

I’d recommend either building a lot of them (for your own personal use). Or going in with a couple of friends.

Conclusion

There you have it…our review of the 80% Arms Easy Jig Gen 3.

If you’re decently handy and want an AR that you literally built yourself (without those pesky serials)…it could be the easiest way.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Again, take a look at our full video review from Johnny B. to see the process from beginning to end.

Are you going to attempt an 80% project now? Check out our Best 80% Receivers article as well as our Definitive AR Guide to get all the best parts for your future build.

25 Leave a Reply

Oh, thanks guys! You really know how to make a person feel bad. Yeah, I like "easier". I want the "smoothest look" and "simplest process". But you hit the nail on the head: I'm "already rolling with the Gen 2" that I purchased about two years ago. I can't afford another $300+! So yes - I will just have to "keep on keeping on" with my Gen 2.

The Easy Jig Gen 3 is stupidly simple to use for anyone who has some DIY experience with hand tools and hand-held power tools. First time out I took my time and didn't try to take too much of a bite with each increment. Got one 6061 lower with the jig (combo on significant sale), used a Makita hand-held router, and used the 6061 to get through the learning curve. Have two 7075 lowers in queue to mill and drill. This isn't something you're going to do on your kitchen table unless you don't mind eating shards of aluminum for a month. Having a shop vac also helps cleanup, and in cleaning out the lower periodically during milling. It makes a considerable amount of tiny shards. I've seen photos of lowers made using other jigs, including the Gen 1 and Gen 2. The Easy Jig Gen 3 is the best I've seen yet, and its router end mill with guide is a quantum leap by an order of magnitude over the old jigs made for drilling out a lower with a hand drill or drill press.

Is there a difference in the 308 receiver and a 7.62 receiver?

I'm trying to find out if the easy jig gen 3 will mill the rear take down pocket. Found a good price on a lower but it states the rear take down is not milled, all the 80% lowers I have purchased so far have the rear pocket already milled,I do have the gen 3 and looking at the milled receivers, it looks as though it might mill enough out but not sure.

Yes . . . it will. The 80% I bought with it has that pocket milled out, but the first guide "pins" will have the router and mill bit going back to create the pocket if it doesn't exist. When I was done and ready to change to the second guide pins it had just barely skimmed the bottom of the pocket.

Easy Jig Gen 3

The bit for the router was not true and ended up breaking on the first pass. The bit is junk.

80% Arms may sell one of the best jigs according to this article. But this company sucks!! It’s been over a month! No return calls, no answer to my emails! You are boating about a company that should be shit down!! Are they just steeling the money from paying customers?? You be the judge! They have mu money! Zero communication!! No parts! No nothing, but they took my money!! The sad part is you are backing them as a top pick! Makes me rethink about you and your!

Maybe you should focus on your spelling, they probably cant understand your emails...

Maybe you should take a step back and look who you are backing! My comments are true and accurate!! Maybe if you spent more time helping them with their customer service instead of critiquing my spelling, you and they would have more business!!!! Customer service is everything in any business!! My spelling and fat fingering the key board has little to do with or correcting the issue at hand!!

AGAIN!! They have and do provide the best quality product on the market, but their customer service SUCKS!!! Maybe I struct a nerve with you Tim, as maybe these comments are pertaining to you!!! If you can not provide customer service and provide your product in a time manner, maybe you should hire some professional help or sell out to someone that will. I have a buyer in hand to purchase your company! Let me know if you wish to sell.

Maybe you should take a step back and realize who youre talking to. Maybe if you spent more time thinking and proof reading you wouldnt look so silly right now. Did i strike a nerv with you Dean? Or should we call you Karen? Cause youre acting like a Karen. What makes you think im.in any way shape or form.in customer sevice lease of all this companies? Are you that dense Karen? What comoany am I selling? I highly doubt your double wide counts as a down payment for anything Karen. Now breath, relax go back to being Dean, youre not you when your hungry.

Maybe you should learn to spell check Karen!! You ask my opinion, and when you get it, you act like a Biden Democrat. Grow up! Everyone has opinion and dealings (sometimes more that once) with others and state facts and you get butt hurt! Grow up Biden, Don’t ask if you don’t want to hear it!! Fact is fact and truth is truth and you can stand it, poor little Biden!!

Ive done numerous lowers with the easy jig 2. The last think I want to do it stop and play with nuts on the bottom of the router.

So, the big question is, do you end up with a 1st class firearm? I am considering building a .308 AR-10. Will it be as accurate as say, a DD5 v4 or v3? I am very comfortable with power tools and do a bit of woodworking. If need be, my brother is a professional machinist with 40 years experience and can assist, not that his experience will matter much with the gen3 jig though (I am guessing).

Don't have your brother help you. YOU have to do it or you may run afoul of AFT.

I've followed the instruction that 5D tactical provided with their jig and for the life of me I cannot understand why I'm having issues with the safety engaging on my AR-15 lower. It's the most frustrating thing I've done. It's not that I'm not handy or haven't machines before, I am and I have but for the life of me I can't figure out what the hell I'm doing wrong. Anyone else have any problems with the safety not engaging after using this jig and billing out an AR-15 lower?

I had this issue with 2 lowers I milled with the Easy Jig 2. I thought I would like the bottom of the fire control pocket as thick as possible to make it really strong. The trigger would install, but the safety either couldn't be installed or just wouldn't turn. You must mill full depth in the "B" pocket of the jig. Go clear to the bottom! Put the lower back in the jig and mill a little deeper. Then reinstall your trigger and safety. Yes, you will have to uninstall your bolt catch, magazine release and front pivot pin. It's a pain, but on the positive side you will learn how to do this. When milling an 80% lower, I install and test the trigger, hammer and safety first; if okay, then I finish the lower parts kit installation. (Also, the safety will only engage if the hammer is cocked.)

Does the easy jig 2.0 do 223 and 308 and do you sale parts to complete entire gun

AS it states in the article, yes, you can mill AR15 (.223) and AR10 (.308) lowers with the Easy Jig 2 Multi-platform. You can also mill AR9 (9mm) lowers with it. The less expensive Easy Jig 2 (not multi-platform) will only mill AR15 and AR9 lowers.

This site doesn't "sale" anything. It's a review and guide site. Go to 80% arms website for the Easy Jig or 5D tactical for their similar, router based, jig.

What about finish on the new bare aluminum interior and in the holes? Can you send them out? Spray-paint? Recommendations?

I DuraCoated and baked my 80% lower.

I leave mine bare.

Beto won’t be finding any of these!

Is it me or do the outside edges of your fcg router job appear very thin?

I think it's the photo. Look at the selector hole wall thickness in the pic of lower with parts arranged on mat.

One thing I learned the hard way Go buy the cutting fluid. WD-40 is petroleum based and will eff up certain " parkerized" finishes. Also,based on experience, when you're milling the oval hole for the trigger 1/4 hashmarks work best and go very slowly as the end mill has a tendency to flex when you're cutting that deep