Updated 9.27.23 with newer information and photos.

So you got a new piece of glass for your rifle. But before you head to the range, you need to get everything mounted up.

Scope mounting is one of those things that is easier than it seems while also being a task where permanently damaging something is fairly easy.

Today, we will cover the basic steps of how to properly and safely mount a scope. No frills here, just a basic rundown.

Table of Contents

Loading…

Steps for Mounting Your Scope

Get the Proper Tools

This first step is the part most people skip, which can easily lead to improper installation and potentially cause permanent damage to the scope, rings, or other parts.

We highly recommend two things — a torque wrench and a set of gunsmith bits.

The torque wrench allows you to set the wrench to stop at a specific number of inch-pounds, preventing you from over-torquing or under-torquing the screws.

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Screws that are too tight can strip threads or even crush the body of the scope, while ones that are too loose can cause you to lose zero.

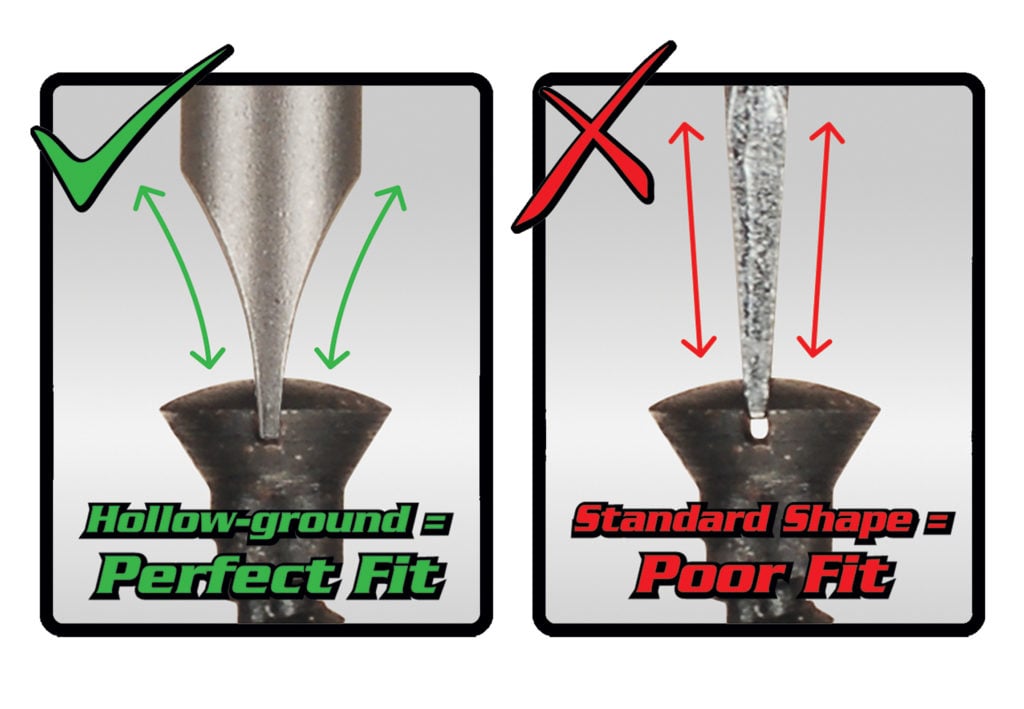

Getting proper bits is also essential. Using cheap or wrong-sized bits can cause you to strip the screw heads and risk things getting stuck or being unable to tighten them.

Lastly, grab a small bottle of blue Loctite. The scope ring manufacturer should specify whether Loctite is required or not, but it is cheap and good to have on hand.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Mount Your Scope Bases

Some rifles do not have scope bases already on the gun and require bases to be installed separately.

The torque spec for the base is almost always different than it is for the rings. You can usually find the torque spec for the base in either the manual for the base, on the manufacturer’s website, or sometimes in the manual for the rifle itself.

Ensure you have the correct bases to mount to your receiver, line the holes up, apply a small dab of Loctite (if specified), set your torque wrench to the correct spec, and screw the base(s) into the receiver.

Once the bases are mounted, check the firearm by cycling the bolt or action to ensure the screws in the receiver are not contacting the bolt at all or causing the action to seize up. If there is any binding, shorter screws will be required.

For rings with integrated bases, the mounting process is still the same.

Mount Your Rings to Your Scope Base

If your rings and bases are not integrated, you will need to mount the bottom half of your scope rings to the scope base.

Loosen the bottom portion of your scope rings and seat them in the slots of the scope base.

Use the recommended torque value to secure the scope rings to the base. This is typically around 30-45 inch-pounds.

Install Your Optic

Place your optic in the scope rings and then put the top half of the scope rings on and install the ring screws, but do not tighten them all the way.

You want to tighten them very lightly until it is barely holding the scope in place while still allowing you to move the scope back and forth and tilt it left and right.

The scope rings should not touch the magnification ring, the turret saddle, or the objective bell.

Shouldering your rifle with a natural head position should yield a complete sight picture with no black edges. Set your scope to maximum magnification and move the scope back and forth until this is achieved.

You can also level your scope during this time, making sure the reticle is aligned perfectly. You can read more about scope leveling in next week’s article.

Tightening Your Rings

Once your eye relief is set and the scope is leveled, you must tighten the scope rings.

Set your torque wrench to the appropriate number and tighten each screw a little bit at a time. Do not completely tighten each screw before moving on.

The goal is to maintain even spacing of the gaps on both sides of the scope rings during the tightening process. We recommend gradually tightening each screw in a criss-cross pattern, as shown below.

If the gaps on both sides of the rings look even, continue tightening to the specified torque spec, and you are all done!

Final Thoughts

Mounting a scope is fairly straightforward, especially with the right tools.

However, there are a ton of different types of rings and mounts, each of which installs a little differently. Our goal was to create a general guide for some of the more common types of rings. If you are unsure, always check the manufacturer’s website for manuals or FAQs.

Tell us about your mounting experiences below! Have a red dot you that mounted but haven’t zeroed? Check out our guide on How to Zero a Red Dot!

11 Leave a Reply

Nowhere, no matter how I phrase it can I find an article about WHERE to mount a scope. I want to hear the pros and cons of mounting a scope above the bolt breach( which elevates the scope) or forward of the bolt breach ( which extends the eye relief) . Please help!!!???!!!

Ryan Cleckler's guide on YT is solid.

As a machinist, I can't help but cringe at the sight of those cheap no-name calipers. Do yourself a favor and get you some Mitutoyo, Brown and Sharpe or Starrett.

Roger that! Cheap calipers can read wrong and dial types with a dirty pinion gear will read OK at say .500" and skip .050" elsewhere on the scale, you'll only know when it goes wrong! I got rid of all the dial type calipers operators used on the New Brittian Multispindle machines yrs ago, scrap dropped right after that!

You didn't say a thing about what "power" you set the scope to while setting for eye relief.

I usually start out on the maximum power, then check it at lower magnification. Some scopes have such a huge variance between the eye relief at maximum power and minimum power that it's nearly impossible to set the scope so that you have a comfortable shooting position at both settings. In this situation, it is best to set eye relief with the scope set on the power that you will be using the most and then work back and forth between the other settings so that you have to adjust your shooting position as little as possible between settings.

I generally use my scopes at nearly maximum power, and hardly ever at lowest power. However, I still make sure that I have as little variance from my normal head position as possible at the lower magnifications while having the optimum eye relief at maximum power.

It is also important to check eye relief at different shooting positions, standing, sitting at a bench, sitting on the ground, propped, kneeling, and any other position you might find yourself in. It really sucks to get out to the range and to lay down behind your rifle, only to find out that the eye relief is so far off that you have to make adjustments before you can shoot, even though it was fine while shooting from the bench. A great scope, with an adequate "eye box" can make your life easier, but it's best to make sure that your scope is set for as many different positions as possible. I always start out at the position that I shoot from the most and then work through to the ones I find myself in the least.

So, as you can see, it ain't as easy as this article tried to make it seem. However, it is worth the effort... and, at least for me, fun.

Great info! The "bubblizing" the scope/rifle/mounts for levelness is the time consuming, detail stressing part of the process. I wrote to all the scope, ring, and mount manufacturers, and asked them to put perfect 12 o'clock index lines on all their products to minimize the bubbleizing required. As usual- birds chirping, crickets creaking, wind through the pines response. But if the rail is square, the rings are square to the mount/rail, and the scope is square to the rings; Little index lines would cut mounting time by 90%, and you could spend more fun time, shooting accurately!

Be careful when using Rubbing Alcohol. Look for 96%. 91% is OK, but do not use anything less. Rubbing Alcohol typically has lanolin added to it. If you are looking to degrease parts, lanolin will not help you.

Don't want to be too nit picky, but when you tighten the 4 or 6 screws on the rings make sure the gap on either side is approximately even. The gap on the left hand between the upper and lower halves of the ring is about the same as the gap on the right hand side. You can get equal torque and have one side pinched and a huge gap on the other side.

P.S. I love this website, awesome info!

Wow! Thorough, to the point, great visuals and outstanding guidance. Plus recommendations of quality tools that won't brake the bank. You guys do it right! I'm looking forward to more!

thanks for the continuous stream of useful info. i will go back and remount my scope!

Excellent info, I would add/adjust one aspect. When leveling the scope I prefer to use a plum bob line some distance out in front, looking through the scope on its lowest mag, clocking it to align the vertical cross hair to the plumb line, (double check to be sure your action is level first and still level after clocking the scope). In this way you are sure your cross hairs themselves are level/plumb to Earth and level to the action.

Thank you again for another excellent article.